|

Picture |

Description |

|

A good planetary gearbox is essential

for turboprop engine. After a thorough research into internet, I came

to this conclusion that no factory products for my need are available so I

must build my own. Retrofitting used gears to build the prototype

would be a great choice because they are easily available from eBay or other

popular online marketplaces. However not all parts can be

bought from internet, ring gear is the one for example. After the design is

validated all the gears will

be mass produced from blanks. Picture shows all the used parts I got for

building the gearbox. |

|

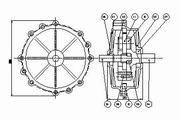

Planetary gearbox assembly plot. The

reduction ratio of this gearbox is : 1+99/15 = 7.6, where 15 is the number

of tooth

for sun gear, and 99 is the number of tooth

for ring gear. Use differential type if

larger reduction ratio is needed. Here's the building plan : 1. cast

aluminum housing(2 halves needed) then turn/drill/tap; 2. turn/drill/tap output

shaft; 3. turn/mill p-gear retainer; 4. retrofit p-gear by turning away the

unneeded pinion; 5. input shaft will be

used as-is, no modification needed; 6. cut ring gear; 7. source lock pins

and bolts, bearings etc. |

|

Rusty round stocks for turning retainer and

output shaft. You might dispute that output shaft should be turned

from casting of similar shape, rather than from such big diameter of blank. Yes, to save material and machining time,

casting is the better way for preparing it, but please remember this holds

for mass production only, for prototyping, to skip one process usually means

both more time and cost effective. So this time we chose to use directly the round stock for

convenience. |

|

Shaft work in progress. Actually the

left part of this shaft is another half of the retainer, this is reason why

we need to turn such a big bar. Phew ! still a long way to go, a lot

of material need to be removed...I swear I'll cast the blank to shape,

next time. |

|

Lathe turning of retainer and shaft

completed. Retainer on the left, shaft on the right. |

|

Lathe turning of retainer and shaft

completed. Shaft is viewed from the back. |

|

Reaming the bearing seat of output

shaft. The work piece is secured on an index head. Click on the picture to see the video clip. |

|

Drilling/milling work of output shaft

completed. Viewed from the rear. |

|

Drilling/milling work of output shaft

completed. Viewed from the front. From this side you see four bearing seats

and 6 lock pin holes, 3 bolt holes. |

|

Milling work of retainer. Work piece is

secured on an index head, and using end mill tool to do the work. |

|

Retainer work piece, milling work is

still proceeding. |

|

Retainer work piece, bearing seat

completed, holes drilled, but gear housing is still not completed. |

|

Retainer completed. Gear housing is

turned. In this case 4-jaw chuck is needed. |

|

Engineering change No.1. After

calculation, these gears unfortunately have to be abandoned due to strength

concern. I need bigger gears for transmitting large torque. So new

gears will be cut with larger tooth width. gear housing will be changed in

accordance. |

|

Shaft with lock pin inserted. These

lock pin holes were drilled with very high position accuracy, so when

assembling the other half, it won't get into trouble matching. |

|

I need some extra space for housing

bigger planetary gears, so 3 spacers out of 6mm SS41 plate are laser cut.

Laser cut holes are accurate in position but the surface finishing is not so

good. Use drill to remove the burrs. |

|

3 spacers are assembled onto disk of

output shaft. when pushing the spacers in place, it is really nice and easy,

fits perfectly. |

|

Well the gear + shaft assembly looks

almost like this. Bearings are still missing. |